Titan 2 HR

High Resolution SLA DLP 3D Printer

- Versatile, high-resolution, high-speed 3D printing between the following resolution ranges for micro applications:

>> 26 ~ 50μm

>> 23 ~ 38μm - Maximum build height up to 9.8 in

- Patented PSP (Passive Self-Peeling) technology:

>> Passive double peeling mechanism

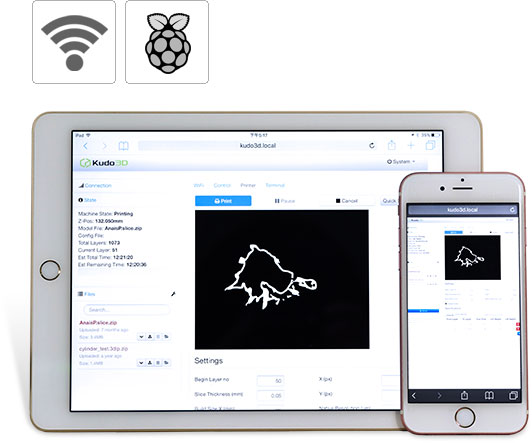

>> Enhanced printing speed and surface quality - Web based controlling:

>> Compatible with all PCs, Macs, smartphones and tablets - One device can be used to control multiple Titan 2 HR 3D printers

- Built-in Raspberry Pi

- Shutter to reduce background exposure

- Calibrated at 23μm or 26μm XY resolutions

- Long lifetime: Mechanical structure is all-metal and designed to last for 10 years

Titan 2 HR Specifications:

Printing Features:

- XY resolution (HD native pixel size): 26 ~ 50μm or 23 ~ 38μm

- Z resolution: 5μm (native gear resolution)

- Build Size: 44.16 x 24.8mm at 23 μm XY resolution

- Maximum print speed:

2.7 in / hr for XY: 50μm and Z:100μm resolution

Hardware:

- Machine Size: 16.1″ x 13.7″ x 33.6″ / 41cm x 35cm x 85cm

- Weight: 30 lbs / 13.5 Kg

- Flexible PSP resin container

- THK’s high precision industrial grade linear stage module

- HD DLP projector with a 2cm native 1920×1080 DMD chip by Texas Instruments

- Raspberry Pi 3 with 16G memory

- Compatible with 802.11n Wifi

- Heavy duty metal frame & case

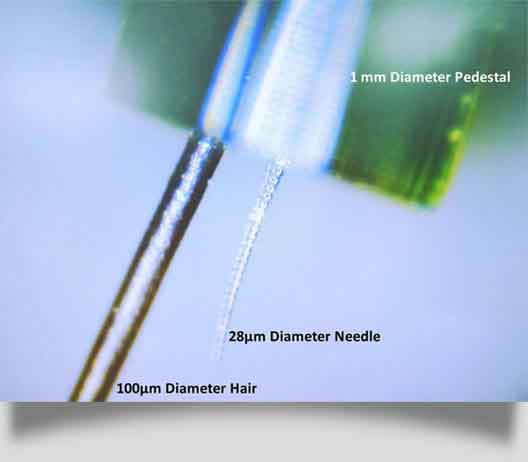

(28μm diameter needle printed at 23μm XY resolution)

Ultra High Resolution 3D Printing

A new innovation sprouts from a single idea. We, at Kudo3D, know how this works. With countless hours of design and experimentation, our SLA DLP high resolution 3D printers have been created with you in mind. We guarantee the reliability and flexibility in the creation of your project. From super detailed microfluidics designs to large engineering models, your ideas can be transformed into a reality. Experience the possibilities with Kudo3D’s Titan DLP 2 HR SLA high resolution 3D printers today!

Titan 2 HR & Titan 2 3D Printer

| Titan 2 HR 3D Printer | Titan 2 Printer | |

|---|---|---|

|

Titan 2 HR 3D Printer with Green Emerald Cover |

Titan 2 3D Printer with Red Ruby Cover |

|

2 PSP Resin Containers (1 Soft + 1 Hard) |

2 PSP Resin Containers (1 Soft + 1 Hard) |

|

Small Build Platform |

Small Build Platform |

|

Large Build Platform |

|

500 gram of 3DSR UHR Resin |

1 Kilogram of 3DSR DX Black Resin |

|

| Price (USD) | $4,799 (23~38μm) |

Testimonials

I purchased a couple Titan 1s a year and half ago to replace the $100,000 3D printer I have been working with for 10 years. Performance of Titan 1 is just as good as that of the high end 3D printer. I have been printing almost every day and produced more than 4000 customized rings over the last 18 months. My customers are also very happy about the casting results. The printers are super reliable and require little maintenance and calibration after they are set up. I am very happy with my Kudo3D printers and decided to purchase another Titan 2 to increase my capacity further.

I’m really pleased with my purchase of the titan 2 dlp 3d printer. Sure, there is a learning curve but Kudo3D staff helped me all the way through it during my first two weeks, flawless customer support ! Great high resolution 3D Printer, high details, very fast and many different resins to choose from for every type of work since you have full control of the printing parameters. I will add that is a plus for me to have an open source 3D printer with most of the parts easily accessible. All in all I’m an happy customer who now print a lot !

Pasamos mucho tiempo investigando los diferentes tipos de impresión FDM, Láser y DLP SLA. Finalmente nos decidimos por la tecnología SLA por su gran calidad. Tras ésto, escogimos la TITAN1 de Kudo 3D por su gran adaptabilidad y por ser Open Source, aunque esto no es del todo imprescindible ya que el software que incluye tiene todo lo necesario para adaptarse a cada modelo y resina y es muy configurable. Ésto ha sido fundamental ya que ningún modelo es igual y poder establecer parámetros distintos en cada impresión hace que puedas imprimir cualquier pieza.

We spent a long time investigating the different printing options in the market; FDM, Laser and DLP SLA. Finally, we chose the SLA technology for its great quality and high resolution. After that, TITAN 1 by Kudo3D was the best option for its great adaptability, being Open Source, and low maintenance. The Open Source option was no longer an essential, because the software that comes with the TITAN 1 includes all the necessary settings to adapt to all models, different resins, and is highly configurable. This has been fundamental in our jobs, because every print is a new challenge. The tools provided by the TITAN 1 allow you to print all kinds of high resolution models.

I love my Kudo3D Titan 1, it allows me to print larger and faster than the other options out there at a resolution that really shows off the details I put into my work. There’s nothing else I’d rather use to bring my digital creations to life.

Before using the Titan 1, I used another laser-based SLA desktop 3D printer for rough prototypes. I then spent $800 a month on high-end 3D prints from several different vendors printing on $35,000 machines. The Titan 1 has replaced that other SLA desktop printer and that $35,000 machine. That $800 a month now comes to me and I have enough business that I purchased a second Titan 1. Forgot to mention that the lifetime of the resin container is superior. We are able to print ultra high resolution miniatures for over 500 hours per

container.

For the past couple of years we have been using two other desktop DLP 3D printers and before we purchased the Titan 1, print size was limited because of a smaller build envelope. We are replacing our smaller build printers with a second Titan 1 for our projects that require 50 microns XY resolution and sub 50 microns high resolution printing – all within a larger build envelope. Printing with the Titan 1 has resulted in an overall reduction in our printing costs. With increased print speed, a lower print failure rate, and the need to use fewer supports, we realize a reduction in printing time, material use, file setup and post processing time. Above all, the resin container has a lifetime that other printers cannot match. Set supports, slice, and press run!