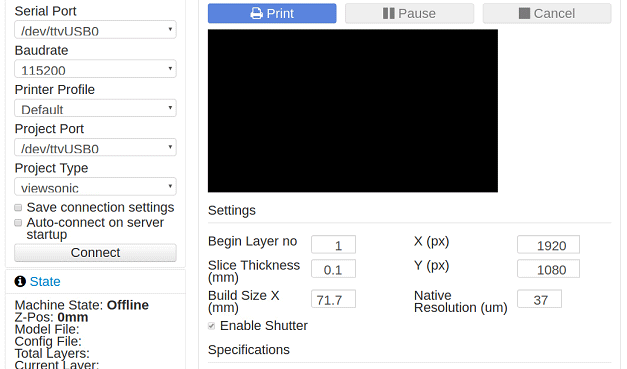

Another key part of learning the printing process is to understand how to set the printing parameters within in the Kudo3D software. There is no “one-fits-all” parameter number that can be duplicated for any type of resin or with any type of 3D design. This being said, the printing parameters will differ every time you have a new resin or have a very different model. However, rest assured! There is a general guideline that you can follow in successfully creating the ideal printing parameter for each print.

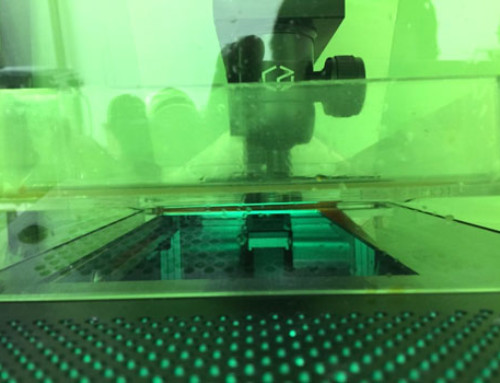

To start off, it is important to understand how the Kudo3D Titan 1 and Titan 2 work. Both printers come with an US patented passive self-peeling technology. The cured layer is peeled away from the resin container, without an additional actuator, when the build platform is lifted. Please refer to our PSP blog to better understand how the PSP works: http://www.kudo3d.com/understanding-kudo3d-psp-resin-container/

There are 5 parameters that you may need to adjust for the layers to speed up the printing process or to improve the print quality. Let’s discuss the impact of these parameters on your print. Afterwards, we will break it down the steps and provide a guideline regarding how to setup these parameters.

- Exposure time: Exposure time has an impact on the resolution, the hardness of the cured material, and the adhesion between the cured layer and the Teflon film. The normal exposure time depends on the resin being used and the layer thickness. Please note that the normal exposure time could drift away due to the aging of the projector lamp or the resin. To identify the normal exposure time, please refer to the article in http://www.kudo3d.com/understanding-kudo3d-high-resolution-calibration-model/

- Lifting height: The platform must be lifted to a height that gives enough time for peeling process to be completed. This number depends on viscosity of resin, adhesion between the cured layer and the Teflon film, lifting speed, exposed area, exposed pattern, and builds platform area.

- Lifting speed: This number usually depends on the strength of your material and the adhesion between the cured layers. The separation force is higher when the lifting speed is higher. If the material is not strong, a high lifting speed may break the model. If the adhesion between the cured layers is not strong, a high lifting speed may tear the model apart.

- Lowering speed: This number has an impact on very fine and weak structure. When the model is lowered at a high speed, the pressure exerted from the liquid resin will also be higher. If the structure is weak, this pressure could temporarily or permanently move the printed model in a micro scale. As a result, you could see more abrupt layer interfaces under the microscope. Sometimes, fine structures could also be distorted. When the viscosity of the resin is higher, the pressure is higher, meaning that you may need to slow down the speed even further.

- Delay: When the platform is lowered in the resin, it will push the resin away. “Delay” is the time required to stabilize the resin. When the viscosity is higher, it takes more time to stabilize the resin.

In general, for each model, we can separate the layer zones into two sections. The first section involves both vacuum force and the adhesion force. The second section usually only involves adhesion (unless the cured layer has a large area). The following guideline is a rule of thumb for setting up the printing parameters. You can tune it up after gaining more experience.

First Section: (first 2mm for small build plate and 4mm for large build plate)

First zone

First layer only- This layer is called attachment layer, which is part of the base and the most important layer.

Exposure time

- 10 to 20 times the normal exposure time to make sure that any potential gap between the build platform and vat floor is fully cured and the first layer is attached to the platform firmly.

Lifting height

- Large build platform: 7 mm

- Small build platform: 5 mm

Lifting speed

- 10 mm/min

Second zone

Rest of the base layers- Normally, the base layers includes all the layers before the supports. The total thickness of base should be thinner than 0.3 mm.

Exposure time

- 5 times the normal exposure time defined with the calibration sample

Number of layers

- Depends on the thickness of the layers and base

- For example, if the base is 0.3mm and the layer thickness is 0.05mm, then you have 5 or 6 layers for the base.

Lifting height

- Large build platform: 7 mm

- Small build platform: 5 mm

Lifting speed

- 10 mm/min

Third zone

The rest of the layers that make up the first 4mm of a model using large platform or the first 2mm using small platform. This zone has the vacuum force influence. Please note that if your z-zero sinks below the Teflon film, the number of layers in the vacuum force section should include the number of layers that brings the platform from z-zero to the actual vat floor.

Normally, this zone contains only supports. This is part of the foundation so it must be strong and stable. You can adjust the number of layers accordingly depending on whether the resin viscosity is higher or lower.

Exposure time

- Half of the second zone

Number of layers

- For example, if the layer thickness is 0.05mm then you have 40 layers for the first 2 mm of printing with a small build platform. If the base consists of 6 layers, the remaining 34 layers will be assigned to this zone.

Lifting height

- Large build platform: 5 mm

- Small build platform: 3.5 mm

Lifting speed

- 15 mm/min

Second Section:

Fourth zone

This zone normally contains layers for supports plus a few layers of the model to make sure that the adhesion for the tips is strong. This zone is also part of the foundation.

Exposure time

- Same as the third zone

- If the model has supports close to the securing aluminum bar, you need to increase the exposure time about 2 times.

Lifting height

- 3.5 mm

Lifting speed

- 15 mm/min

- If the bottom of the model has a flat surface and the model is not rotated, the first few layers that attaches to the support tips usually has a larger area. Since the separation force is higher for large exposed areas, you might want to slow down to avoid the tips breaking off.

Fifth zone to Seventh zone

Layers for both supports and model

Exposure time

- Gradually lower the exposure time from the 5th to 7th zone to avoid horizontal lines caused by non-uniform layer shrinkage.

Lifting height

- Ranges from 2mm to 5mm, depending on the exposed area

Lifting speed

- 15 mm/min

Eighth zone and more

Layers for model only. These layers consist of purely model slices.

Exposure time

- Normal exposure time

Lifting height

- Ranges from 2mm to 5mm, depending on the exposed area.

Lifting speed

- 15 mm/min

This provides the basic overview of how to set up the printing parameters within the Kudo3D software. As mentioned before, there is no “one solution that fits all” for any type of resin or model. Being said, the best method to understand how to set parameters is to have as much practice and experience as possible. Once you understand how the numbers are set and why they are set as so, you will have a much easier time in creating parameters for different types of models!

Hi,

When you refer to large and small areas exposed, which would be the limit between both types of ares?

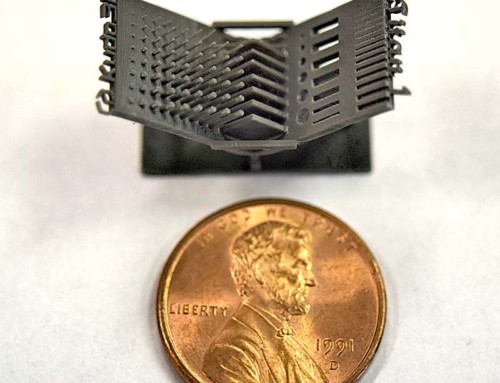

Small means miniatures or any models smaller than that. A cube of an inch is not small as the cross sectional area is large enough to warp the Teflon film. Therefore, soft containers are usually for small and high resolution models.

Small and large is more determined by the exposed cross sectional area.

Thanks you so much. Good quality work. Go ahead.

Thank you for your comment. We are working hard to make resin printers better, especially for high resolution and precision.

Is it possible to tweak variables like exposure time and active pixels to have multiple resolutions within one layer in the XY plane?

You can use grey scale to change the intensity of light instead of the exposure time. However, not sure if there is a slicer that can do this.

So my basic question as a beginner (new Bean owner), is how do we determine the “Normal Exposure Time” for each resin and layer height? As it is now, I’m merely using the exposure times shown in the basic parameter data for each 3DSR resin. But I’m sure there’s a better way, as for instance i THINK those are for 50 micron layers. So of course adjustments need to be made for thinner and thicker layers.

And that’s where it gets experimental (and expensive / time consuming). Is there a “one stop shopping” source which provides normal exposure times for each resin at varying layer heights?

Thanks!

Please visit the blog for the article about our calibration sample.

Thanks for sharing this information! So useful.

I have also read an article on the same subject here, with some good points too

https://ufo3d.com/outsource-3d-modeling-services-5-misconceptions

Where is admin?

I’ts important.

Regards.

Please send an email to contact@kudo3d.com