For a bottom up stererolithography 3D printer, a cured resin layer may stick to the vat floor and be hard to separate. Silicone is often used as the vat floor because of its elasticity that can facilitate the separation of cured layers. However, the resins will gradually react with silicone and the silicone will turn hazy after printing a couple models. Sometimes, the cured layer will bond with silicone tightly and cannot be separated. Some use a wiper to replenish oxygen on the surface of silicone to extend the lifetime of the vat. Doing this increases the complexity of the printer and the service cost. In addition, it increases the printing time and requires a much larger resin container.

For us, we simply attach a thin Teflon film to protect the silicone from contacting the resin directly so as to extend the lifetime of resin container. You might think that Teflon is a non-stick material. In general, it is true, but some cured resin materials can stick on the Teflon film firmly and are very hard to separate. The followings are the reasons why a cured layer could be hard to separate.

- Some cured resin has a strong Van Der Waals’ force with Teflon. When the cured area is large, the separation force is high.

- Over-cured resins tend to have a much higher adhesion to Teflon.

- Hollowed model without vent holes could introduce tremendous suction force.

- Bulk shrinkage in a tapered solid region could turn a flat layer into a bowl like shape that could also introduce tremendous suction force. A thin cone shape is more likely to happen. This phenomenon often happens when:

- a. Material itself has a high native shrinkage

- b. Fast curing ( < 1 second) due to strong light intensity or more photoinitiator concentration could introduce higher shrinkage for the same material

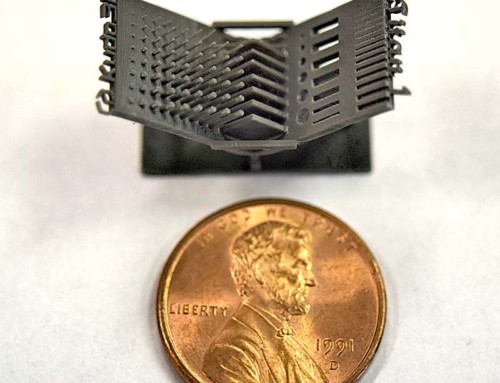

- c. For a fast resin, low separation speed introduce more on-going curing after the light is turned off. Low separation height does not mix the resin near the curing area with fresh resin outside the curing area well enough so the viscosity becomes higher in the curing area gradually. The combination of the above two could introduce differential shrinkage between layers and across the layer and form a strong suction effect. The situation is more severe when printing repeated patterns. This suction force may result in a phenomenon where the cured layer suddenly sticks to the Teflon and does not come apart (as shown in the photo). To provide an example, suppose a certain resin has a normal exposure time of 1 second. During the printing process, the resin has absorbed photons from both background and scattering exposure near the exposed area. Please note that the resin in the build area close to the vat floor tends to have higher viscosity when partially cured and tends to stay near where it is. If the accumulated absorbed dosage is equivalent to 0.5s of normal exposure, the next print layer will technically be over cured for 1.5 seconds (1 second for the exposure time + 0.5 second from already being cured due to background and scattering exposure). During the buildup of the partially cured resin, the effective over-curing will keep increasing the adhesion between the cured layer and the Teflon film. If you cannot use another slow resin instead, you would need to increase the lifting speed and lifting height to slow down the buildup.

How will the above affect your print? They will significantly affect the consistency of the separation force and increase the failure rate. Even if the print survives, the surface quality may be deteriorated. They will affect both the Teflon film lifetime (please refer to the PSP resin container blog ) and the printing quality.

Knowing the reasons as to why high adhesion occurs and the solution to it will greatly smooth out your printing process. Even if your print did not come out the way you expected, it is important to understand why it happened. This way, you know what the cause of the problem is and learn to avoid it next time. Learning from failed print is perhaps one of the best way to quickly learn and understand more about SLA printing!

Leave A Comment